Metals

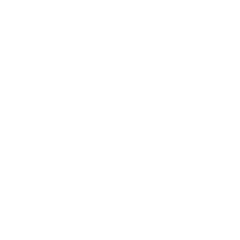

Signode India offers total packaging solutions to the Steel and Metals Industry. This includes hot and cold mills, rod and bar applications, metal service centers, aluminum and other non-ferrous Metals.

Signode India's product offering includes steel and plastic strapping, protective packaging materials, and a full range of packing films and papers offering corrosion protection. Container, rail and ship lashing solutions ensure safe transit.

Signode India designs manufactures and supplies strapping tools and semi-automatic and fully automatic packaging machines to apply these packaging materials. A highly focused parts and service group offers customized service helping to lower your total cost of ownership.

To meet industry’s growing needs, we also offer printing & labeling systems and integrated warehouse management solutions.

With our team of industry specialists we design your complete pack, including the provision of materials and equipment for your market. Metal Industry Solutions lead to greater productivity, optimization of safety, and cost reduction.

Contract Packing can be offered by Signode India to include packing labour, total materials supply, equipment, and administration. This enables customers to focus on core activities, whilst at the same time benefit from specialist attention, process simplification, single point of contact and reduced packaging inventories.

To learn more about Signode India’s protective packaging systems please make your selection from the list below.

Signode Solutions for Metal Industry

Secure Hot rolled Coils using Signode Strapping machines integrating with any steel or aluminium mill layout.

Signodes model M410-CH3A circumferential strapping machine can be located very close to the re-coiler at the exit of the mill. The machine can withstand temperatures up to 800 degrees centigrade.

The CH3 A model can be also supplied to suit most customer rolling mill locations and coil mandrel layouts for new line builds or as a suitable retrofit to an existing rolling line.

Signode Has developed several machine solutions using high performance steel strap and also PET straps. Steel strapping of the coils can be done using the M410 strap head.

AK200 range of strapping heads to be used in a variety of mill applications apply 19,25 and 32mm PET strap of various gauges to coils both circumferentially and radially or through the eye.

The use of Signode high-performance Tenax® Polyester strapping reduces to a minimum any surface damage during strapping

Download Literature

Download Literature NG-CPL

NG-CPL

Round or hexagonal tube bundles can be securely packaged using wither 19-32mm steel strap or with 19-32mm PET Tenax® Polyester strapping, depending upon product weight and tube surface finish.

Here too the machines can be fixed or indexing models. Indexing models can move via a floor mounted system or on an overhead gantry system making all M410 or AK200 strapping systems fully flexible.

Download Literature

Download Literature Bar Rod Bundling & Strapping System

Bar Rod Bundling & Strapping System

Tenax® Polyester strapping is a superior solution for the ingot an billets packaging as the retained tensions on the package are higher with PET than steel, there is no staining of the materials, no indentation of the products.

For ingots the PET is applied in both automatic and semi-automatic systems to accommodate uneven ingot packs, this enables the strap to be applied at high tension to the bundles for stable transportable packages, without the need for bundle compression during the strapping operation. Download Literature

Download Literature

Discover the one-stop for full service

Signode India, offers contract packaging to Key Customers. Contract Packaging can include packing labour, total materials supply, equipment and administration, best practices. This enables customers to focus on core activities, whilst at the same time benefiting from process simplification, single point of contact, and zero packaging inventories.

Contract packaging is a “contract entered with the customer by the company to provide comprehensive solutions for packaging of customer’s products”. The objective of Contract Packaging is to provide packaging solution with single point responsibility at customer premises. The Key processes in Contract Packaging Business are Presales process, Contracting Process and Contract Execution process.

Read More >>

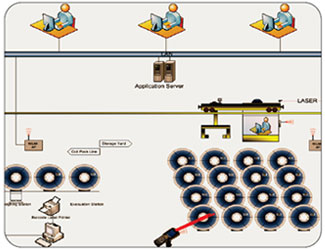

Signode now offers a comprehensive internal logistics infrastructure and process improvement solutions and services. Also, Signode has partnered with the leading global logistics technology solutions providers for process specific solutions.

With the experience of implementing best practices in packaging and identification, handling, storage and shipment practices, Signode is well placed to successfully marry finishing line automation with internal logistics process automation systems in a seamless and visible manner at optimum cost.

Leveraging the understanding of finishing processes, Signode has been looking for ways to contribute to metals industry’s business end to end. Reduction of total cost of operations (TCO) is the expanded focus.

- Slab Yard

- Coil Yard

- Longs Yard Download Literature

Download Literature

ITLMS is a client-server based system primarily developed for managing the slab, coil, longs yards of any metal industry. It is designed for tracking the movement of metal products through the value chain through real-time material tracking, regulation and reporting.

ITLMS’s scope includes inward yard management, scheduling and tracking inventory through various processes, yard location/space management, dispatch planning including load building and material staging and logistics terminal management.

This is just not a software package but encompasses all control functions related to crane, transfer cars, coil conveyors essentially required material tracking functions. The main elements of ITLMS are crane automation, server, RF Network, hand held terminal. Download Literature

Download Literature ITLMS

ITLMS

Click on the below tabs to see the full list of Signode packaging products and solutions