Signode is known for developing customised packaging solutions for various industries. Our compelling range of solutions for the timber industry, backed by our global expertise and deep local presence, set us ahead of our competitors.

Signode’s steel strap solutions include our seal-less manual combination tool (SCM) and battery-powered Grip Pack range of tools.

For PET strap, Signode leads the way with the BXT3 battery powered combination tool, the world’s first touch screen technology tool. The intuitive display keeps operation simple with visual displays of tension values, sealing time and indication of Auto, Semi-Auto or Manual mode. The BXT3 will retain two sets of strapping parameters making it quick and efficient to switch between applications. Additional features such as the blow through vent for clearing dust from the tool makes the BXT3 a firm favourite in the rugged environment of the timber industry. |

|

|

|

| Signode’s strapping machine with a modular design separates each of the functions into individual operating modules that can be removed by hand without the use of tools or lifting equipment. This means that modules are switched over in approximately two minutes and production continues uninterrupted as modules are serviced off line. |

|

|

The Signode Robotic NM2000 Batten Feeder brings a new level of reliability and technology to the timber and panel industry through the ability of the robot to read the position of the batten before attempting to lift it. In a production environment, battens are seldom presented in perfect neat stacks. Inevitably battens are out of square and in random positions, causing problems for conventional solutions. NM2000 detects the position of the batten and quickly adjusts its angle of approach to suit lifting and placing with precision.

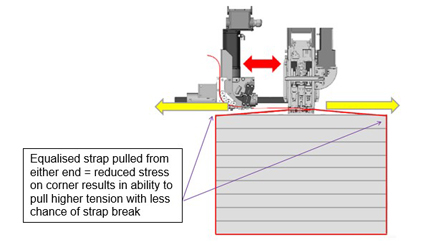

Retained Strap Tension is a key factor to maintain secure loads through the logistics cycle. We have developed the Z30 strapping solution that can be fitted to multiple press solutions. The modular system has three key modules - Feed, Take-up and Sealing. The key to the Z30 achieving the highest levels of retained tension lies in the method of applying tension to the strap. |

|

|

|

Convention has tension being applied to one end of the strap by a tension wheel while the other end is held by a gripper in the strapping head. Signode’s Z30 grips both ends of strap, one in each head on the press. The heads then drive apart on a rack-and-pinion applying tension evenly from both ends and overcoming the problem of lost tension at each corner that the strap passes over in the conventional method. Higher strap tension is achieved with less force applied to the corners of the pack, reducing the chance of damage and reducing the risk of strap breaks through over-tensioning. |

|

|

Additional benefits of the Signode Z30 include improved safety with strap being fed into the system from outside of the Safety Access Zone. The Feed Module is located at ground level and is easy to reach, avoiding operators having to climb onto the machine to feed strap to the head.

Automatic refeed further improves productivity by avoiding stoppages. The Z30 can detect blockage in the strap path and then automatically withdraw the strap from the chute and refeed it up to three times, usually clearing the obstruction and successfully completing the strap cycle.

With the vast range of solutions, Signode is best equipped to provide customized solutions for the specific needs of customers in the timber industry. |

|

|