Usage of stretch film for surface protection has been the most effective way of protecting the product from moisture and damage. However, its composition (LLDPE - linear low density polyethylene) makes it environmentally unsustainable. Signode has now developed a path breaking innovation by introducing Oxo-biodegradable stretch film which while retaining all the properties of the conventional stretch film, also breaks down into smaller biodegradable particles, when exposed to sunlight and oxygen.

Till date, there has been little success in usage of recycled raw material in manufacturing of stretch film. Signode’s Oxo-biodegradable stretch film will go a long way to support environmental sustainability. Oxo-biodegradable is a term for petroleum-based plastics with small amounts of an additive or a catalyst to accelerate the biodegradation process. Oxo-biodegradable plastic uses metal salts to start degradation and to speed up the process, which result in extremely small fragments of plastic that no longer ‘visually pollute the environment’. Further degradation depends on living organisms and bacteria. |

|

|

|

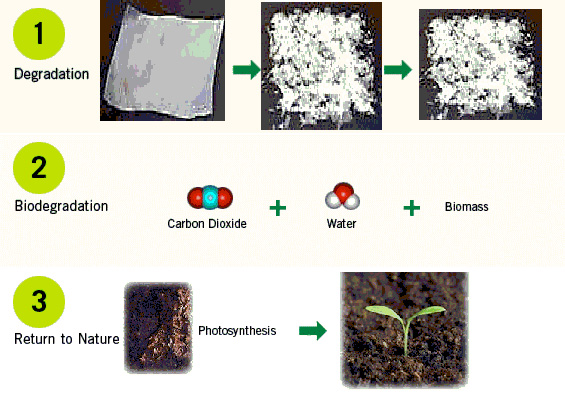

The typical stages in the breakdown are as per below:

Stage 1 - Film breaks down in open environment, into small chain organics

Stage 2 - The organic material is biodegraded by bacteria present in environment, into non-toxic residue

Stage 3 - The residue is bio-degradable non-toxic soil, which can be used to grow plants and is comparable to soil control. |

|

|

| The impact of plastic packaging on the environment has always been a major concern for all the producers and consumers. Rigorous efforts have been made to either reduce or eliminate plastic packaging. Oxo-biodegradable stretch film is poised to revolutionize the packaging industry. |

|

|

|