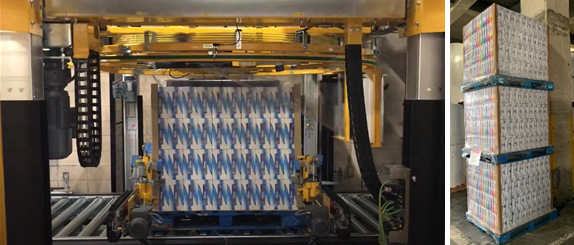

Signode team in Japan worked with a major paper manufacturer to develop a tissue paper box palletization solution for large supermarket customers. Signode solution consisted of Top Sheet, Angle Board Corner Protectors and Stretch Wrapping for ensuring pallet stability and safety during transit.

Signode installed its Octopus B 1825 stretch wrapping machine equipped with automatic Corner Post Device applying mechanism (CPD) and Top Sheet Applicator to meet the high productivity needs of the customer.

The Octopus wrapping machine is an automatic rotary ring stretch wrapper for use on pallets. Using Mima Film stretch wrap, the wrapping film reel is suspended from a ring and it revolves around the pallet. The ring is raised and lowered according to the wrapping program. The pallet remains stationary, which makes the wrapping of unstable and lighter loads or products considerably easier. There are no centrifugal forces to cause strain or stress on the load or on the equipment. The ring can be accurately positioned in the vertical direction, wrapping can be started and finished at any height required. The Octopus provides optimal load containment while minimizing film usage.

BENEFITS OF OCTOPUS MACHNE:

- Fast production throughputs – for production lines of up to 190 pallets per hour with the Twin head model & 100 pallets per hour with single head model

- Maximum machine up-time - due to its solid aluminum construction and long lasting parts

- S style feed – vastly improving stretch and lowering costs over traditional W style machines

- Versatile design can accommodate a wide range of different pallet sizes

- Lower cost of ownership - easy service & low maintenance needs

- Ensures no ‘tail’ is left for improved health & safety

Signode has led this packaging change for truck load shipments in the paper segment, and it is expected to pick up in future in Japan |

|

|

|

|

|